Inspection services involve the visual examination, testing and evaluation of equipment, structures, or systems to ensure compliance with regulations requirements, standards and safety requirements, as well as identifying any defects or issues that require maintenance or repair. To prevent malfunctions and accidents, this service involves evaluating the state, safety and compliance of roads, buildings, bridges, pipelines and electrical systems. These inspections make sure that machines are running correctly, which helps to prevent equipment downtime. Regular inspections are an essential component of almost every plant's or facility's overall maintenance schedule. It is necessary to inspect and then service mechanical, electrical and instrumental systems

Turnaround services are the planned shutdowns of the plant or unit

for inspection, maintenance and repair. Turnaround services involve

planning, coordination and execution to minimise downtime and

maximise efficiency during the shutdown period.

Turnaround: execution, management and planning.

Painting services involve applying paints or coatings to industrial structures, machines and facilities with the intention of preventing them from rust or corrosion, making them use effectively and maintain uniformity for all the items belong to industry or company. These services are very important of ensuring longevity of the machinery and integrity of the industrial facilities. Our Industrial painting contractors are familiar with environmental regulations regarding VOC (Volatile Organic Compounds) emissions and proper disposal of paint waste.

As the leading industrial services provider, we are capable of handling all stages of projects, from pre-shutdown to post-shutdown activities. Our scaffolding team is always ready for swift and safe execution. We will provide advanced-quality scaffolding adhering to all safety procedures and our team is prepared to execute diverse projects, regardless of location, at any time. Our qualified professionals design a safe and efficient scaffolding plan based on your project needs and site specifications. We have trained crews to ensure proper assembly and disassembly of the scaffolding structure, adhering to safety regulations. Regular inspections throughout the project ensure the integrity and safety of the scaffolding. We also offer rental options for various scaffolding types, allowing you to pay for the time you need the equipment. We are committed to ensuring that the scaffold are built most effectively, versatilely and in compliance with all relevant safety standards and regulations

Industrial insulation services are the unique one which has been defined for enhancing different industrial indexes such as energy, safety, performance etc We maintain heat, sound, or electricity from speeding. It is used around the globe in power generation plants, refineries and manufacturing units. Some of the services include the application, re-application, inspection/ repair of insulating and heat tracing materials on different equipment’s and structures like pipes, tanks, boilers and ducts. There are some Key benefits and aspects of industrial insulation services includes;

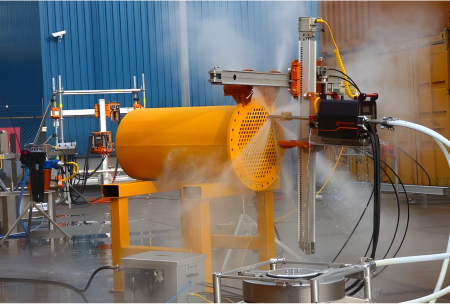

Chemical cleaning is the process of removing scale, corrosion, or deposits from equipment or piping systems to increase efficiency and prevent fouling. In industrial settings, specialised chemicals and methods are most frequently used to handle hard cleaning tasks, such as cleaning machinery, structures, pipelines, and equipment. These services, which involve the detection of rust, scale and other contaminants, are essential to the integrity and efficacy of the core structure. In addition, they might provide industrial tanks, heat exchangers, boiler tanks and other machinery maintenance and cleaning services. The chosen chemical cleaning service provider needs to have the necessary knowledge, tools and safety precautions, not to mention that they need to follow the established procedures when carrying out the work, greatest quality and functionality, this field is associated with experts like engineers, welders and project managers.

The columns, which are vertical containers used for distillation, absorption, etc, come under the manufacturing sector, such as petrochemicals and refining. Maintenance involves cleaning, inspection, and repairs to maintain optimal performance. This includes corrosion control, painting, structural integrity checks and ensuring safety regulations. All of these will help to maintain a secure and safe environment and ensure optimal performance without downtime. We offer maintenance, considering the specific requirements, needs and infrastructure of the client. These may include types of maintenance, budget considerations and frequency of inspection.

Vessels are machines in which fluids are kept and processed under pressure. Vessel maintenance includes inspection, testing and repair to prevent leaks or failures that could result in hazardous situations. Maintaining vessels guarantees that they continue to operate at their best. Our quality control system ensures that your final product has been properly constructed, inspected and hydrostatic pressure teste

This can be accomplished by treating water with hydrogen, which can eliminate contaminants like sulphur or oxygen that are frequently used in industrial processes to create high-quality water for a variety of uses. Injecting hydrogen gas into water and causing a reaction between the reactants is known as "water hydrogenation." These processes have a variety of applications, including the production of hydrogen and the purification and treatment of water. Hydrogenation has the potential to contribute to the decomposition of pollutants and enhance the quality of water by transforming certain pollutants into innocuous substances or by increasing the effectiveness of other purification techniques. Hydrogenation is a technique that can be used in wastewater treatment to break down organic compounds and lower pollution levels. Alternatively, hydrogen can also be used in isolation to electrolyze water and produce hydrogen gas, which can then be used to power clean energy sources in a variety of applications.

The service deals with the manufacture and installation of piping systems for industrial processes, that is, the preparation according to the design, making the welds and assembly of the pipes following standards and examinations. Our service includes the fabrication and installation of piping systems for various applications, such as water supply, drainage, heating and cooling. These services provide hydraulic fluid transportation that guarantees reliability and efficiency while complying with the sector’s criteria and standards of safety. To ensure the production of leakproof piping systems of the greatest quality and functionality, this field is associated with experts like engineers, welders and project managers.

Tank maintenance service is the regular inspection, cleaning and repair of storage tanks used in various industries to maintain high standards for which these tanks can store liquids or gasses. This includes checking for leaks and corrosion to ensure safety regulations. These maintenances are crucial to avoiding costly repairs and uninterrupted operations. Additionally, proper maintenance will reduce the risk. In the event of emergencies such as leaks, spills, or structural failures, tank maintenance services may provide emergency response capabilities to mitigate risks, contain the situation and prevent further damage.

Valves regulate the flow of liquids or pressurised gases inside pipeline systems. Valve maintenance includes inspection, lubrication and repair to ensure they operate smoothly and prevent leaks. Lubrication of the valve reduces friction and makes the opening and closing of the valve easier. Check the stuffing box gasket for wear and damage and replace it to stop leaks. If the stuffing box nut is loose, tighten it as well. Regularly clean the internal components and open the valve. Frequent maintenance lowers the chance of unscheduled by identifying possible problems before they become more serious. You can maintain the cleanliness of your industrial valves with a maintenance programme and correct installation.

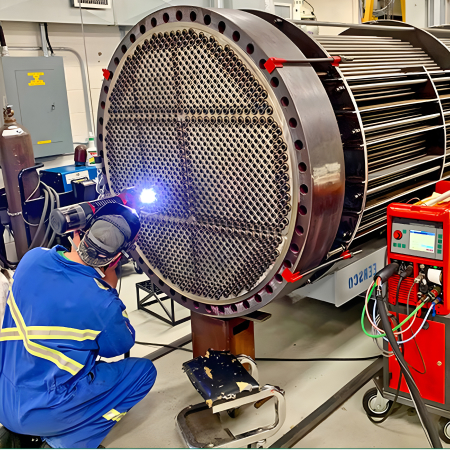

We have the capability, machines and procedures to fabricate, modify and repair heat exchangers. To regulate a process's temperature, exchange heaters transfer heat from various fluids. Maintenance involves cleaning, inspecting and repairing heat exchangers to ensure efficient operation. To keep a heat exchanger operating at peak efficiency, maintenance is necessary. Fouling, corrosion, or other issues will lower the heat exchanger's performance. Additionally, maintenance helps to avoid urgent repairs that would require downtime. Certain heat exchanger types have longer lifespans than others.

Flares are essential tools in the oil and gas industry because they help eliminate excess gas. Mechanical maintenance ensures these structures function properly, minimising environmental impact and ensuring safety. A dedicated unit with a comprehensive portfolio of flare and chimney services, many of which can be performed via rope access, thereby saving on the expense of cranes and scaffolding. Alirtjaz is your all-in-one maintenance partner for every flare type and size used in the onshore and offshore industries.

These services all revolve around instruments such as heaters, reactors, and reformers that are used in chemical reactions or heating. Maintenance ensures these critical components operate efficiently and safely. Alirtjaz Mechanical Services has developed a strong mechanical engineering division to support your operations with maintenance, overhauls, upgrades, repairs and installation work on all types of stationary equipment.